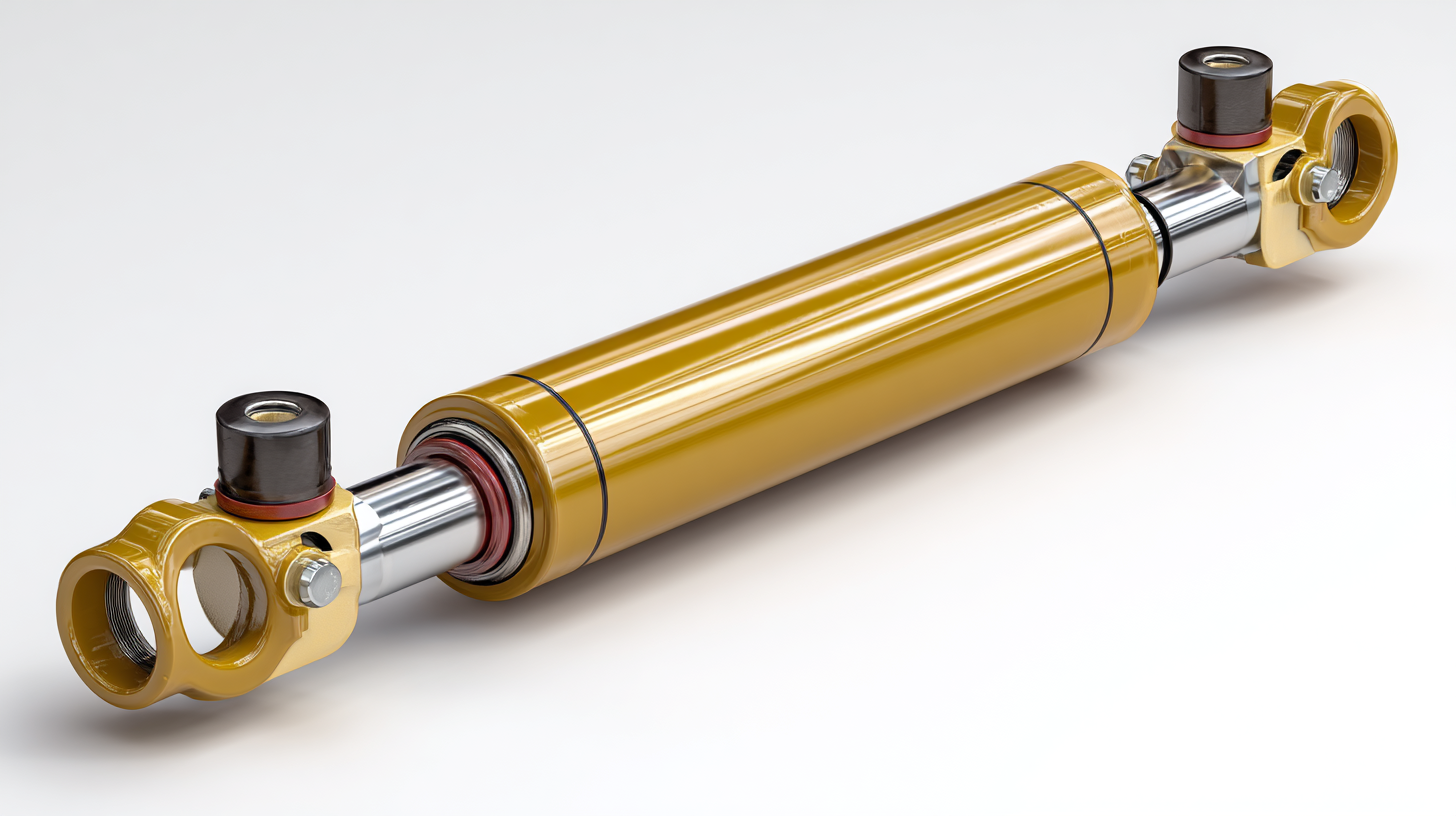

10 Best Hydraulic Cylinders for Trailer That Enhance Performance and Durability

The trailer industry has witnessed significant advancements in technology and engineering, particularly with the integration of hydraulic systems. A pivotal component in enhancing the performance and durability of trailers is the hydraulic cylinder for trailer applications. According to a report by the International Journal of Engineering and Advanced Technology, the demand for efficient hydraulic systems in the automotive sector is projected to grow by 6.5% annually, driven by the need for more powerful and reliable machinery. This growth underscores the importance of selecting high-quality hydraulic cylinders that can withstand the rigors of towing and heavy loads.

With a plethora of options available, choosing the best hydraulic cylinder for trailer use can significantly impact operational efficiency and safety. Research from the Society of Automotive Engineers indicates that properly selected hydraulic cylinders can improve load handling capabilities by up to 30%, thereby enhancing overall trailer performance. Moreover, durability is a crucial factor, as well-maintained hydraulic systems have been shown to reduce maintenance costs by 25%, allowing for longer service intervals and less downtime. This article will explore the ten best hydraulic cylinders for trailer use in 2025, providing insights into their features, benefits, and contributions to performance enhancement.

Understanding Hydraulic Cylinder Types and Their Applications in Trailers

Hydraulic cylinders are essential components in trailer systems, enabling various operations such as lifting, tilting, and steering. Understanding the different types of hydraulic cylinders is crucial for selecting the right one for your trailer's needs. The most common types include single-acting cylinders, which use hydraulic pressure to move in one direction and rely on gravity or external forces for retraction. They are ideal for trailers that require simple lifting mechanisms, such as dump trailers.

Hydraulic cylinders are essential components in trailer systems, enabling various operations such as lifting, tilting, and steering. Understanding the different types of hydraulic cylinders is crucial for selecting the right one for your trailer's needs. The most common types include single-acting cylinders, which use hydraulic pressure to move in one direction and rely on gravity or external forces for retraction. They are ideal for trailers that require simple lifting mechanisms, such as dump trailers.

On the other hand, double-acting cylinders provide movement in both extending and retracting directions, making them suitable for applications that require controlled positioning. These cylinders are beneficial for trailers involved in more complex tasks, such as flatbeds or those with specialized attachments. Additionally, there are telescopic cylinders, which are particularly advantageous for trailers needing a compact design and extended reach during operation. By comprehensively understanding these cylinder types and their specific applications, trailer owners can enhance performance and durability, ensuring their equipment operates effectively and efficiently in various conditions.

Key Performance Metrics: Load Capacity and Pressure Ratings for Hydraulic Cylinders

When selecting hydraulic cylinders for trailers, two key performance metrics stand out: load capacity and pressure ratings. The load capacity indicates the maximum weight a hydraulic cylinder can lift, making it critical for trailers that transport heavy loads. Selecting cylinders with appropriate load capacities ensures safety and prevents mechanical failure, which could result in costly repairs or accidents. Manufacturers typically provide specifications that detail these capacities, and it's crucial to match them with the expected load to maintain optimal performance.

Pressure ratings provide insight into the operational efficiency of the hydraulic system. They represent the maximum pressure the cylinder can withstand during operation without risking damage. High-pressure ratings are often necessary for trailers working in demanding environments or under heavy loads. Choosing cylinders with the right pressure rating enhances the durability and functionality of the hydraulic system, allowing it to perform reliably over time. When evaluating options, it’s essential to balance both load capacity and pressure ratings to ensure that the hydraulic cylinders installed on the trailer will deliver outstanding performance and longevity.

Material Selection: The Impact of Steel vs. Aluminum in Cylinder Durability

When it comes to hydraulic cylinders used in trailers, the choice of material plays a crucial role in determining their durability and overall performance. Steel and aluminum are the two predominant materials, each offering distinct advantages.

Steel hydraulic cylinders are renowned for their strength and resistance to deformation under heavy loads, making them a favored option for heavy-duty applications. Their ability to withstand extreme conditions and provide a longer service life makes them ideal for trailers subjected to rigorous use.

Steel hydraulic cylinders are renowned for their strength and resistance to deformation under heavy loads, making them a favored option for heavy-duty applications. Their ability to withstand extreme conditions and provide a longer service life makes them ideal for trailers subjected to rigorous use.

On the other hand, aluminum hydraulic cylinders present a lighter alternative that is beneficial for increasing fuel efficiency and ease of handling. Aluminum's resistance to corrosion is another significant advantage, particularly for trailers that frequently encounter moisture or harsh environments. While they may not match the tensile strength of steel, advancements in aluminum alloys have significantly improved their performance, allowing them to serve effectively in various applications. Ultimately, the selection between steel and aluminum will depend on specific use cases, weight considerations, and environmental factors, ensuring that the hydraulic cylinder enhances both performance and durability.

Maintenance Best Practices: Extending the Lifespan of Hydraulic Cylinders for Trailers

Regular maintenance is crucial for ensuring the longevity of hydraulic cylinders used in trailers. One of the best practices is to inspect the cylinders for any signs of leakage or wear. Early detection of issues can prevent more significant problems that could compromise performance. Ensure that seals and fittings are tight and replace any damaged parts promptly. Cleaning the cylinder regularly helps remove dirt and debris that can cause friction and wear, ultimately enhancing its lifespan.

Additionally, proper lubrication is vital to reduce friction and improve the efficiency of hydraulic cylinders. Use the manufacturer-recommended hydraulic fluid to avoid any chemical reactions that could damage the seals. Check fluid levels regularly and top off as needed, ensuring that the system operates smoothly. It's also essential to monitor operating conditions, such as temperature and load limits, to prevent over-stressing the cylinders. By following these maintenance best practices, trailer owners can significantly enhance the performance and durability of their hydraulic cylinders.

Performance Comparison of Hydraulic Cylinders for Trailers

This chart compares the performance metrics of various hydraulic cylinders used in trailers, including lifting capacity, cycle time, and durability rating. It helps identify the best options for improving efficiency and longevity.

Market Analysis: Leading Brands and Innovations in Hydraulic Cylinder Technology

The market for hydraulic cylinders has witnessed significant growth, driven by advancements in technology and an increasing demand for enhanced performance in trailer applications. Leading brands have invested heavily in research and development, focusing on innovations such as lightweight materials, improved sealing systems, and smarter integration with electronic control units. This has led to hydraulic cylinders that not only perform better but also have a longer operational lifespan.

In addition to performance improvements, manufacturers are placing greater emphasis on durability. The development of corrosion-resistant coatings and high-strength alloys has made hydraulic cylinders more resilient to harsh working environments. Brands like Parker and Eaton are at the forefront of these innovations, offering products that cater to both the heavy-duty demands of trailers and the need for reliability. As the trailer industry continues to evolve, the focus on technological advancements in hydraulic cylinder design will play a crucial role in meeting customer expectations and enhancing overall system efficiency.

Related Posts

-

Maximizing Efficiency: The Advantages of Upgrading Your Hydraulic Oil Cylinder Systems

-

7 Essential Tips to Maximize Efficiency with Hydraulic Oil Cylinders: Improve Performance by 30%!

-

Understanding the Best Hydraulic Oil Cylinder Types for Your Needs

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders