Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift

In the competitive landscape of material handling, selecting the right hydraulic cylinder for forklift applications is critical for optimizing efficiency and safety. According to the International Journal of Advanced Manufacturing Technology, approximately 25% of forklift accidents are linked to equipment failure, emphasizing the importance of choosing compatible and reliable components. With the forklift market projected to reach $65 billion by 2025, driven by the growing e-commerce sector and increasing automation in warehouses, the demand for high-performance hydraulic systems is on the rise. A well-chosen hydraulic cylinder for forklift not only enhances lifting capabilities but also contributes to overall operational productivity.

This ultimate checklist aims to guide you through the crucial factors to consider, ensuring your selection aligns with both current industry standards and your specific operational needs.

Understanding the Different Types of Hydraulic Cylinders for Forklifts

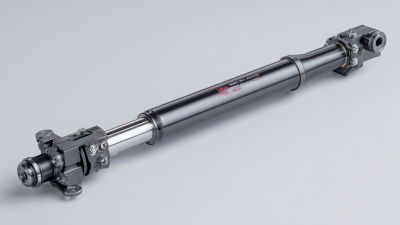

When selecting the right hydraulic cylinder for your forklift, it's essential to understand the different types available. Hydraulic cylinders play a crucial role in the functionality of forklifts, enabling them to lift and move heavy loads efficiently. There are primarily two types of hydraulic cylinders typically used in forklifts: single-acting and double-acting cylinders.

Single-acting cylinders rely on hydraulic pressure to extend and a spring or gravity to retract, which makes them ideal for applications requiring less frequent adjustments. In contrast, double-acting cylinders utilize hydraulic pressure for both extending and retracting movements, offering more control and power, making them suitable for heavier and more dynamic loads.

Single-acting cylinders rely on hydraulic pressure to extend and a spring or gravity to retract, which makes them ideal for applications requiring less frequent adjustments. In contrast, double-acting cylinders utilize hydraulic pressure for both extending and retracting movements, offering more control and power, making them suitable for heavier and more dynamic loads.

The global hydraulic cylinder market has been witnessing robust growth, reflecting the increasing demand for efficient lifting solutions in various industries. With the market projected to grow from USD 14.3 billion in 2021 to USD 18.3 billion by 2027, advancements in hydraulic technology are further enhancing performance and reliability. Forklifts equipped with advanced hydraulic systems not only improve operational efficiency but also ensure safety on the job site by providing stable and controlled lifting mechanisms.

Understanding these key distinctions in hydraulic cylinder types is crucial for making informed choices that align with the specific needs of your operations.

Key Benefits of Using High-Quality Hydraulic Cylinders in Forklift Operations

When it comes to forklift operations, the importance of high-quality hydraulic cylinders cannot be overstated. These components play a pivotal role in ensuring efficient and reliable lifting capabilities, ultimately enhancing productivity in various industries. A recent market analysis projects the autonomous forklift segment, which heavily relies on advanced hydraulic systems, will witness substantial growth by 2032, indicating a clear trend towards automation in manufacturing and warehousing sectors. High-quality hydraulic cylinders contribute significantly to the performance of these automated systems, enabling smoother operations and reducing maintenance costs.

Investing in premium hydraulic cylinders not only boosts the operational efficiency of forklifts but also directly impacts safety. Subpar cylinders can lead to malfunctions that compromise safety standards, resulting in potential hazards in bustling warehouse environments. Moreover, with the increasing use of Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), the demand for durable and reliable hydraulic components has surged. Industry reports suggest that businesses utilizing high-quality hydraulic systems can expect up to a 20% increase in overall equipment efficiency, emphasizing the critical nature of these components in contemporary forklift operations.

Hydraulic Cylinder Performance in Forklift Operations

This chart represents the lifting capacity of different quality hydraulic cylinders used in forklift operations. Higher quality cylinders generally provide better performance and reliability in operational settings.

Factors to Consider When Selecting a Hydraulic Cylinder for Your Forklift

When selecting the right hydraulic cylinder for your forklift, several critical factors come into play. First, it’s essential to consider the load capacity and the working pressure of the cylinder. The hydraulic cylinder must be capable of handling the weight of the loads your forklift will typically lift. Inspecting the specifications to ensure that the cylinder can withstand the necessary pressure during operation is crucial for both performance and safety.

Another significant aspect is the cylinder's size and stroke length. The dimensions need to match your forklift's design to allow for smooth operation and to achieve the required lift height. Additionally, evaluating the type of mounting is vital; different applications may require specific mounting styles to ensure stability and control during lifting. Lastly, consider the material and construction of the cylinder, as this will affect durability and maintenance requirements. Opting for high-quality materials can prevent premature wear and enhance the lifespan of the hydraulic system.

Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift

| Factor | Description | Importance Level | Recommended Specifications |

|---|---|---|---|

| Load Capacity | The maximum load the cylinder can lift. | High | Determine based on lifting needs (e.g., 5 - 10 tons) |

| Stroke Length | Distance the cylinder can extend. | Medium | Match with your forklift's operational requirements |

| Cylinder Type | Type of hydraulic cylinder (single-acting or double-acting). | High | Select based on function requirements |

| Mounting Style | How the cylinder is attached to the forklift. | Medium | Choose compatible mounting style |

| Material | The material of the cylinder affects its durability. | High | Steel or aluminum with protective coatings |

| Seal Type | Type of seals used to prevent leakage. | Medium | Look for high-quality seals to ensure longevity |

| Pressure Rating | Maximum pressure the cylinder can handle. | High | Ensure it matches system requirements (e.g., 2000 psi) |

Maintenance Tips to Maximize the Lifespan of Your Forklift's Hydraulic Cylinder

Proper maintenance of your forklift’s hydraulic cylinder is crucial for maximizing its lifespan and ensuring efficient operation. According to a report from the International Society of Automation, regular maintenance can increase hydraulic component lifespan by up to 30%. Key maintenance tips include checking fluid levels and quality regularly, as low or contaminated hydraulic fluid can lead to significant cylinder wear and tear. Moreover, monitoring for leaks and ensuring appropriate seals are in place will prevent loss of hydraulic pressure, thereby extending the life of the cylinder.

Additionally, experts recommend conducting routine inspections for signs of wear, such as corrosion or pitting on the cylinder’s rod. The American National Standards Institute (ANSI) suggests creating a maintenance schedule, with inspections performed every 200 operating hours, or at least once a month for high-use environments. Proper cleaning and lubrication of moving parts further contribute to smooth operations, reducing the likelihood of unexpected failures that can lead to costly repairs. Adopting these maintenance practices will not only enhance the performance of your hydraulic cylinders but also contribute to overall operational efficiency in your warehouse or construction site.

Comparing Cost-Effectiveness: Standard vs. Custom Hydraulic Cylinders for Forklifts

When selecting hydraulic cylinders for forklifts, one crucial consideration is the cost-effectiveness between standard and custom options. According to a report from the Machinery Research Institute, standard hydraulic cylinders typically account for approximately 20-30% of the overall maintenance budget for forklift operations. These cylinders offer widespread compatibility and reduced lead times, making them an attractive choice for businesses looking to minimize downtime. The average price point for standard hydraulic cylinders ranges between $300 to $600, depending on the specifications and OEM compatibility.

When selecting hydraulic cylinders for forklifts, one crucial consideration is the cost-effectiveness between standard and custom options. According to a report from the Machinery Research Institute, standard hydraulic cylinders typically account for approximately 20-30% of the overall maintenance budget for forklift operations. These cylinders offer widespread compatibility and reduced lead times, making them an attractive choice for businesses looking to minimize downtime. The average price point for standard hydraulic cylinders ranges between $300 to $600, depending on the specifications and OEM compatibility.

In contrast, custom hydraulic cylinders may offer distinct advantages that justify their higher price, often exceeding $800. They can be tailored to meet specific operational needs, significantly improving efficiency and potentially prolonging the lifespan of the forklift. A study by the Industrial Machinery Association reported that custom solutions could enhance performance metrics by up to 15% in high-demand applications. This performance boost, coupled with reduced wear and tear, frequently leads to lower long-term operational costs, even if the initial investment is higher. As such, businesses must evaluate both upfront costs and the long-term benefits when determining the best hydraulic cylinder for their forklift needs.

Related Posts

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Ultimate Guide to Choosing the Right Hydraulic Cylinder for Excavators with Key Specs and Tips

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance