Why Choose Telescopic Cylinders for Your Hydraulic Systems?

Telescopic cylinders play a crucial role in hydraulic systems. Their ability to extend and retract efficiently makes them ideal for various applications. John Smith, an expert in hydraulic technology, often emphasizes, "Telescopic cylinders provide unmatched power in compact designs." This highlights their unique advantage.

In construction and material handling, telescopic cylinders are indispensable. They help lift heavy loads without occupying much space. However, it is vital to acknowledge potential challenges. For instance, maintaining proper lubrication can be tricky. Neglecting this can lead to performance issues.

Furthermore, while telescopic cylinders excel in power, their complexity can raise concerns. Users must ensure they choose the right configurations. A mismatch may result in inefficient operation or even failure. Reflecting on these details can aid in making informed decisions about hydraulic systems.

Benefits of Using Telescopic Cylinders Over Traditional Cylinders

Telescopic cylinders offer remarkable advantages within hydraulic systems. They are designed for high power and compact storage. These devices can extend significantly compared to traditional cylinders. In fact, telescopic cylinders can provide up to three times the stroke length in a much smaller folded length. According to industry reports, many sectors, including construction and manufacturing, have seen efficiency gains of about 20% by switching to telescopic designs.

One crucial benefit is the ability to achieve heavy lifting without a bulky system. This significantly reduces space requirements on machinery. Often, this compact design leads to lower overall equipment costs. However, the higher complexity can also mean more points of potential failure. Regular maintenance and inspections are essential to avoid issues.

Tips: Always consider the specific application when selecting cylinder types. The weight and load requirements are vital factors. Be mindful of the environment; factors like temperature and exposure can affect cylinder performance. Additionally, don’t overlook fluid type; using the wrong hydraulic fluid can cause inefficiencies. Conducting thorough research and ongoing assessments will ensure optimal performance and longevity of your system.

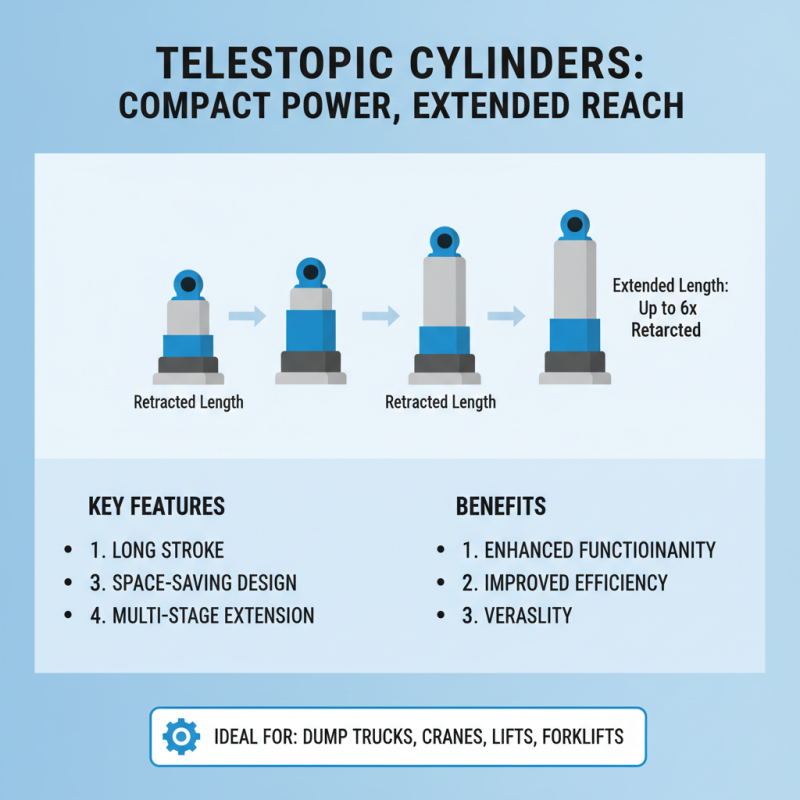

Key Features of Telescopic Cylinders in Hydraulic Applications

Telescopic cylinders are essential in many hydraulic systems. They offer key features that enhance functionality and efficiency. These cylinders can achieve long strokes while maintaining a compact size, making them ideal for applications with limited space. According to industry reports, telescopic designs can extend up to six times their retracted length.

One significant feature is their ability to handle high loads. These cylinders often boast load capacities exceeding 100 tons. Their construction allows for robust performance, making them suitable for heavy machinery and earthmoving equipment. However, high load capacity can present risks. Regular maintenance is crucial to prevent failures, which can lead to costly downtimes.

Another important aspect is their versatility. Telescopic cylinders can operate in various conditions. They are used in construction, transportation, and even waste management. Despite their advantages, some users report challenges in performance under extreme conditions. Temperature fluctuations can affect hydraulic fluid viscosity, impacting efficiency. Keeping these factors in mind is essential for optimizing system performance.

Application Areas: Where Telescopic Cylinders Excel

Telescopic cylinders are widely used in various hydraulic systems. They are particularly advantageous in applications requiring compact design and long stroke lengths. For instance, construction equipment often benefits from these cylinders. A report by the International Journal of Engineering & Technology reveals that telescopic hydraulic cylinders can extend up to 6 times their collapsed length. This characteristic makes them ideal for operating dump trucks and lifts.

In the material handling sector, telescopic cylinders shine. They often thrive in environments where space is limited but long reach is crucial. An analysis by Market Research Future indicates that the demand for these cylinders is projected to grow at a CAGR of 5.2% over the next five years. This surge is driven by the increasing automation in warehouses and factories.

TIPS: When selecting telescopic cylinders, consider the weight they will lift. Ensure proper calculations of force and load. Overestimating capacity can lead to failures. Always prioritize safety in your design. Also, keep an eye on maintenance schedules. A regularly serviced system extends the lifespan of your hydraulic cylinders.

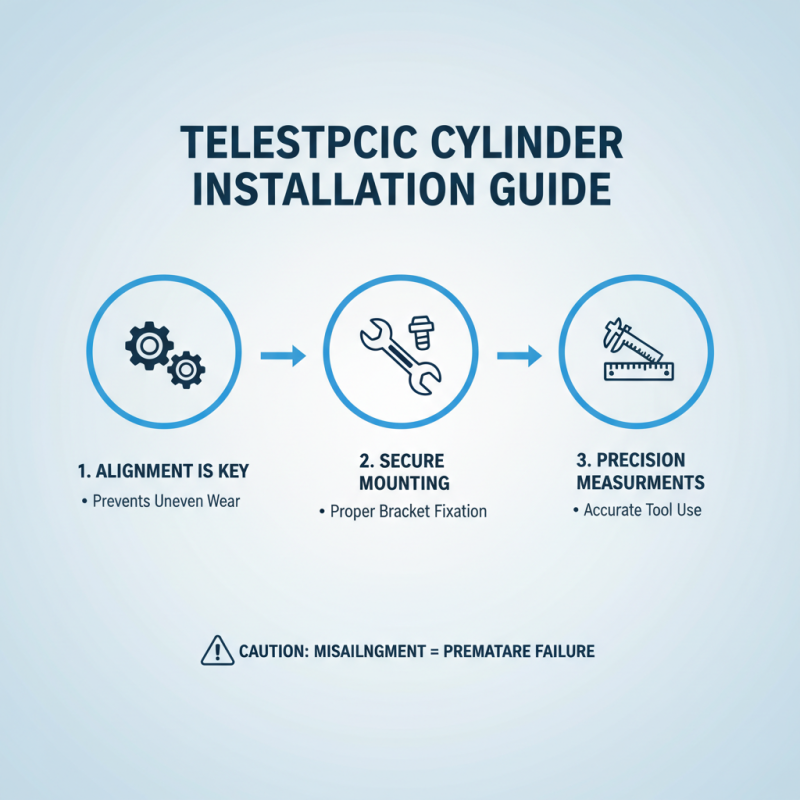

Installation Considerations for Telescopic Cylinders

When installing telescopic cylinders, consideration is vital. These cylinders operate by extending multiple sections, so correct alignment is key. Misalignment can cause uneven wear, leading to premature failure. Ensure the mounting brackets are secured properly. Utilize precision tools for accurate measurements.

Hydraulic systems often have dynamic loads. Review the flow rates and pressure levels they'll encounter. Over-pressurization may damage the cylinders. Pay attention to the ambient temperature as well. Extreme temperatures can affect performance.

It's a common oversight to neglect regular maintenance checks. Dust and debris can accumulate in the cylinder, leading to hydraulic fluid contamination. Use protective seals but remember they can wear out. Regular inspections help identify potential issues early. Always keep an eye on performance metrics. This can save time and resources in the long run.

Maintenance Tips for Maximizing Telescopic Cylinder Performance

Telescopic cylinders play a crucial role in hydraulic systems, providing compact solutions for lifting and pushing applications. To ensure they perform optimally, regular maintenance is key. Check for leaks routinely. These can indicate worn seals or loose connections. Addressing these issues early can prevent costly repairs down the line.

Another important aspect is lubrication. Use the recommended oils and greases. A poorly lubricated cylinder can lead to excessive wear and tear. Monitor the lubrication levels closely. If it seems low, refill it as soon as possible. This step won’t take much time but can extend the life of your hydraulic system significantly.

Be aware of unusual noises during operation. Strange sounds might signal an underlying problem. Ignoring them could lead to bigger issues later. If you notice performance inconsistencies, don’t hesitate to investigate. It's wise to consult a professional if needed, but don't let small problems derail your operations.

Telescopic Cylinder Performance Factors

Related Posts

-

How to Maximize Efficiency with Telescopic Cylinders in Heavy Machinery Operations

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance

-

How to Choose the Right Telescopic Cylinder for Your Industrial Needs

-

Maximizing Efficiency and Performance with Telescopic Cylinder Innovations in the Hydraulic Industry

-

How to Choose the Right Telescopic Cylinder for Your Project Needs

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China