How to Choose the Right Hydraulic Cylinder for Your Trailer?

Choosing the right hydraulic cylinder for your trailer is crucial. Expert John Smith, a seasoned hydraulic engineer, emphasizes, "The wrong cylinder can lead to serious issues." His insight highlights the importance of understanding your specific needs.

Hydraulic cylinders play a vital role in the operation of trailers. They facilitate lifting, lowering, and maneuvering loads effectively. Selecting the wrong hydraulic cylinder for trailer applications can compromise safety and efficiency. It may even lead to costly repairs or accidents.

Many users overlook critical factors like load capacity, stroke length, and mounting options. These elements are essential for optimal performance. Reflect on your requirements before making a choice. An informed decision ensures your hydraulic cylinder for trailer meets the demands of your projects effectively.

Understanding the Types of Hydraulic Cylinders for Trailers

When selecting the right hydraulic cylinder for your trailer, understanding the types is crucial. Hydraulic cylinders are typically categorized into single-acting and double-acting types. Single-acting cylinders use hydraulic pressure in one direction only, making them ideal for applications requiring less complexity. In contrast, double-acting cylinders function efficiently in both directions, providing more control and power. A recent industry report highlights that nearly 70% of trailer users prefer double-acting cylinders due to their performance benefits.

Another essential factor is the cylinder's bore size. A larger bore allows for greater lifting capacity but may increase weight and cost. For instance, a 3-inch bore may lift 5,000 pounds, while a 4-inch bore could lift around 10,000 pounds. Many users overlook these details, which can lead to inadequate support in heavy-duty applications. The material and sealing mechanisms also play a vital role. Cylinders made from high-grade steel are durable, yet not all users recognize the importance of this choice. A poorly made cylinder can lead to leaks and lower efficiency.

Consider the operating environment as well. Corrosion can weaken your hydraulic system. If your trailer operates in adverse conditions, investing in corrosion-resistant options is critical. Data shows that 80% of hydraulic failures are due to environmental factors. Many often rush this decision, missing out on longer-lasting, efficient solutions. Remember, taking time to choose wisely can save costs in repairs and replacements.

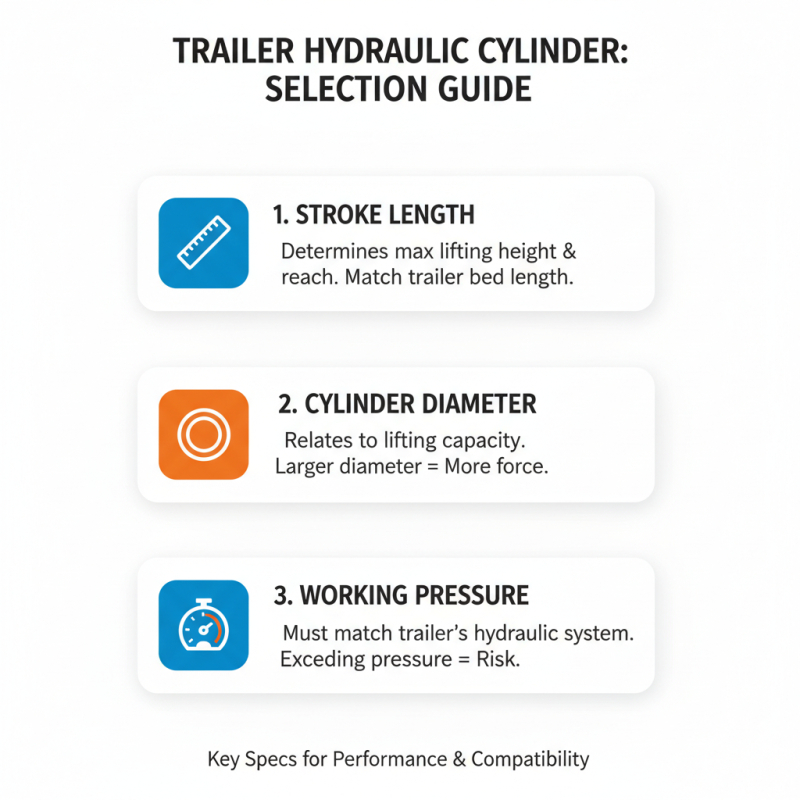

Key Specifications to Consider When Choosing Hydraulic Cylinders

Choosing the right hydraulic cylinder for your trailer involves understanding key specifications. Not all cylinders are created equal. You need to consider factors like stroke length, diameter, and working pressure. Each specification impacts performance and compatibility.

Stroke length is the distance the piston can travel. A longer stroke provides more lifting capacity. However, it can take up more space. Cylinder diameter affects the force produced. A larger diameter means more lifting power but can also add weight. Working pressure determines the maximum force the cylinder can sustain. Ensure it's suitable for your trailer’s application to avoid failure.

Don’t forget about mounting style. Various styles exist, such as pin, clevis, or flange. The wrong style can lead to installation issues. Remember that materials used also play a role. Corrosion-resistant materials are crucial for longevity, especially in harsh environments. Reflect on these aspects carefully. Choosing the wrong cylinder may lead to unexpected challenges. It is vital to assess all these factors thoroughly.

Evaluating Load Capacity and Performance Requirements

Selecting the appropriate hydraulic cylinder for your trailer requires careful evaluation of

load capacity and performance needs. Consider the

weight of the load you intend to carry.

Knowing this helps determine the necessary cylinder size. A hydraulic cylinder's load capacity is

critical. Exceeding its limits can lead to failure and

dangerous situations. Always calculate the maximum weight and add a safety margin.

Tips: Verify the cylinder's specifications

against your load requirements. Double-check your calculations. This might save you from possible

mishaps.

Performance requirements also matter. Think about the speed and frequency of use. A

high-speed operation might need a different type of cylinder compared to one working

slowly. Also, inspect how often the cylinder will be engaged. Frequent use demands a more

robust option.

Tips: Look for materials that can withstand

wear and tear. This can prolong the life of your trailer. Assess your environment too. Harsh

conditions might require additional features. Regular checks and maintenance can also prevent

issues down the road.

Installation Considerations for Hydraulic Cylinders on Trailers

When installing hydraulic cylinders on trailers, careful planning is essential. The placement of the cylinder greatly affects performance. Consider the trailer's load distribution. If not balanced, it may lead to uneven lifting. This can cause safety issues and affect the lifespan of the cylinder.

Another important aspect is the mounting style. You can choose between pin or clevis mounting. Each option has its pros and cons. Pin mounts offer flexibility, while clevis mounts provide stability. Assess your trailer’s design before finalizing your choice. Ensure the mounting brackets are robust. Weak brackets may warp under heavy loads, leading to system failure.

Don't overlook hydraulic fluid compatibility. Using the wrong fluid can damage components. Regular maintenance checks are vital for long-term functionality. Check for leaks or loose fittings frequently. Ignoring these can result in costly repairs. Plan for adjustments during initial use. Sometimes the cylinder may not perform as expected. Be prepared to make modifications for optimal performance.

How to Choose the Right Hydraulic Cylinder for Your Trailer? - Installation Considerations for Hydraulic Cylinders on Trailers

| Dimension | Value | Considerations |

|---|---|---|

| Stroke Length | 18 inches | Ensure sufficient stroke for the trailer's application. |

| Bore Diameter | 2 inches | Bore affects the lifting capacity; choose based on load requirements. |

| Rod Diameter | 1 inch | Thickness influences strength; select for applicable force levels. |

| Operating Pressure | 1500 PSI | Ensure the hydraulic system supports the cylinder's pressure rating. |

| Material | Steel | Select based on durability requirements and environmental conditions. |

| Mounting Type | Pin Mount | Mounting style must align with trailer design and application. |

| Weight Capacity | 5000 lbs | Ensure capacity meets or exceeds trailer usage requirements. |

Maintenance Tips for Ensuring Longevity of Hydraulic Cylinders

Proper maintenance of hydraulic cylinders is essential for their longevity. Regular inspections are crucial. Look for leaks, rust, or any signs of wear. Small issues can escalate if ignored. Clean the exterior to prevent contaminants from entering. A simple wipe can make a big difference.

Lubrication is another key factor. Use appropriate oils and greases. Ensure that all moving parts are well-lubricated. This reduces friction and wear. However, avoid over-lubrication. It can attract dirt and cause more damage.

Pay attention to the seals. They wear out over time. Replacing damaged seals can prevent leaks. Staying consistent with these tasks can greatly enhance your hydraulic cylinders’ lifespan. Regular maintenance is not just a task; it’s a commitment.

Hydraulic Cylinder Performance for Trailers

This chart illustrates the performance capabilities of hydraulic cylinders used in trailers. The data represents different sizes of hydraulic cylinders and their corresponding lifting capacities. Properly selecting the right size is crucial for maintenance and operational efficiency.

Related Posts

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

Essential Checklist for Selecting the Right Hydraulic Oil Cylinder for Your Needs

-

Hydraulic Cylinder For Trailer Common Issues Impacting Performance and Longevity

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

Why Choose Hydraulic Oil Cylinder for Your Machinery Needs?