How to Choose the Right Telescopic Cylinder for Your Industrial Needs

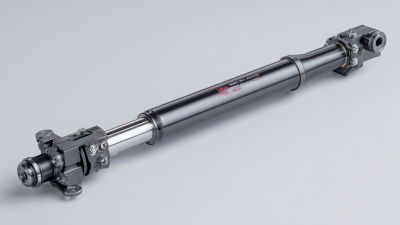

When it comes to industrial applications, selecting the right equipment is crucial for achieving optimal performance and efficiency. Among the various components that play a significant role in machinery operation, the Telescopic Cylinder stands out due to its unique design and versatility. Ideal for situations where space is limited and a high force is required, these cylinders are meticulously engineered to extend and retract with remarkable precision. However, choosing the right Telescopic Cylinder can be a daunting task, given the myriad of types available on the market. Factors such as load capacity, stroke length, operating pressure, and environmental conditions all need to be considered to ensure that the selected cylinder meets the specific industrial needs. In this blog, we will explore essential criteria for selecting the appropriate Telescopic Cylinder, guiding you through the process to make an informed decision that will enhance your operational effectiveness.

Understanding the Key Specifications of Telescopic Cylinders for Industrial Applications

When selecting the right telescopic cylinder for industrial applications, understanding key specifications is crucial to ensuring optimal performance. Telescopic cylinders are designed to provide a significant stroke length while maintaining a compact retracted size, making them ideal for environments with spatial constraints. It's essential to consider factors such as the cylinder's maximum extendable length, collapsing dimensions, and the number of stages, which influences both the lifting capacity and stability during operation.

Another critical specification to evaluate is the cylinder’s pressure ratings. Telescopic cylinders typically operate under high-pressure conditions, and selecting a cylinder that can withstand the necessary pressure is vital for safety and efficiency. Additionally, consider the material composition—steel and aluminum are common choices, with each offering distinct benefits in terms of weight, strength, and corrosion resistance. By taking into account these specifications, businesses can choose a tailored solution that enhances productivity and meets the unique requirements of their industrial tasks.

Top 5 Types of Telescopic Cylinders: Which One Fits Your Needs?

When selecting a telescopic cylinder for your industrial needs, it's crucial to understand the different types available and their specific applications. The top five types include single-acting cylinders, double-acting cylinders, multi-stage cylinders, pneumatic cylinders, and hydraulic cylinders. Each type offers unique benefits and is suited for various tasks, from lifting heavy loads to precise positioning.

When considering which type to choose, think about the operational environment and the load requirements. For example, single-acting cylinders are ideal for applications that require force in one direction, while double-acting cylinders provide force in both directions, making them versatile for many industrial tasks. Multi-stage cylinders are perfect for applications needing significant lifting power and compact design, making them suitable for tight spaces.

Tips for choosing the right telescopic cylinder include assessing the weight of the load, the required stroke length, and the operating pressure. Additionally, consider the maintenance requirements and the environment in which the cylinder will operate, such as exposure to harsh weather conditions or contaminants. By carefully evaluating these factors, you can select the ideal telescopic cylinder that meets your industrial needs effectively.

Evaluating the Load Capacity: How to Ensure Optimal Performance in Industries

When selecting a telescopic cylinder for industrial applications, evaluating the load capacity is crucial to ensure optimal performance. According to a recent report by the International Society of Automation, improper load calculations can lead to 30% of equipment failures in industrial settings. Thus, understanding the maximum load that a cylinder can handle is essential. Telescopic cylinders are designed to provide maximum extension and lifting capacity, often achieving a load capacity range from 1 to 100 tons, based on the application’s specific requirements.

Additionally, it's important to consider dynamic versus static load capacities. Industry standards suggest that the dynamic load should be no more than 80% of the static load capacity to maintain safety and longevity in operation. For instance, if a telescopic cylinder has a static load capacity of 50 tons, the dynamic load capacity should ideally not exceed 40 tons. This ensures reliability during cyclic operations and prevents premature wear and tear. Choosing a cylinder that aligns with these load capacity guidelines not only enhances performance but also plays a significant role in ensuring safety in industrial environments.

Additionally, it's important to consider dynamic versus static load capacities. Industry standards suggest that the dynamic load should be no more than 80% of the static load capacity to maintain safety and longevity in operation. For instance, if a telescopic cylinder has a static load capacity of 50 tons, the dynamic load capacity should ideally not exceed 40 tons. This ensures reliability during cyclic operations and prevents premature wear and tear. Choosing a cylinder that aligns with these load capacity guidelines not only enhances performance but also plays a significant role in ensuring safety in industrial environments.

The Importance of Material Selection: Comparing Steel, Aluminum, and Composite Cylinders

When selecting telescopic cylinders for industrial applications, the choice of material plays a pivotal role in enhancing performance and durability. Steel cylinders are renowned for their high tensile strength and resistance to wear, making them ideal for heavy-duty operations. However, their weight can pose challenges in applications where maneuverability is crucial. On the other hand, aluminum cylinders offer a lightweight alternative, facilitating easier handling without significantly compromising strength. Recent advancements in manufacturing techniques enable aluminum to be used effectively in various applications, though its susceptibility to corrosion remains a concern.

Composite materials are gaining traction in this domain due to their superior strength-to-weight ratio and resistance to environmental stressors. A review of composite materials in automotive applications highlights their advantages over traditional metals, pointing out that composites can reduce weight by up to 30% while maintaining structural integrity. This is particularly relevant in industries striving for efficiency and sustainability. The lessons learned from the automotive sector can inspire similar innovations in telescopic cylinder construction, suggesting that composites could become a mainstream option. Furthermore, studies on burst pressure performance of various tank shapes underscore the potential of composites to withstand extreme conditions, emphasizing their reliability. As industries prioritize lightweighting and performance, the importance of integrating advanced composite materials into telescopic cylinder design becomes increasingly apparent.

Material Comparison for Telescopic Cylinders

Maintenance Tips: Prolonging the Life of Your Telescopic Cylinder in Heavy-Duty Settings

When it comes to operating telescopic cylinders in heavy-duty industrial settings, maintenance is key to ensuring their longevity and reliability. According to a report by the National Fluid Power Association (NFPA), improper maintenance is one of the leading causes of hydraulic system failures, accounting for nearly 20% of downtime in industrial operations. Therefore, following key maintenance tips can significantly enhance the lifespan of your telescopic cylinders.

Regular inspection of seals and hoses is essential. Tips to consider include checking for signs of wear or damage, which can lead to leaks and costly repairs. Additionally, maintaining the correct hydraulic fluid level and quality is crucial; using fluid that meets industry standards can prevent degradation and wear on the cylinder components. The American Society of Mechanical Engineers (ASME) recommends replacing hydraulic fluid every 1,000 hours of operation to ensure optimal performance.

Regular inspection of seals and hoses is essential. Tips to consider include checking for signs of wear or damage, which can lead to leaks and costly repairs. Additionally, maintaining the correct hydraulic fluid level and quality is crucial; using fluid that meets industry standards can prevent degradation and wear on the cylinder components. The American Society of Mechanical Engineers (ASME) recommends replacing hydraulic fluid every 1,000 hours of operation to ensure optimal performance.

Another critical aspect of maintenance is to operate within the manufacturer-recommended pressure limits. Exceeding these limits can lead to premature cylinder failure and negatively affect the overall system. Implementing a monitoring system to track performance metrics can provide insights into potential issues before they result in extensive damage, ultimately saving time and resources in the long run.

Related Posts

-

Essential Checklist for Selecting the Right Hydraulic Oil Cylinder for Your Needs

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

How to Choose the Best Hydraulic Cylinder for Your Trailer Needs