Understanding the Functionality of Excavator Hydraulic Cylinders

Understanding the functionality of excavator hydraulic cylinders is crucial for anyone involved in construction and heavy equipment operation. These powerful components are the heart of an excavator's hydraulic system, enabling the machine to perform a variety of tasks with exceptional precision and strength.

Understanding the functionality of excavator hydraulic cylinders is crucial for anyone involved in construction and heavy equipment operation. These powerful components are the heart of an excavator's hydraulic system, enabling the machine to perform a variety of tasks with exceptional precision and strength.

In this blog, we will delve into the mechanics behind excavator hydraulic cylinders, explaining how they operate and their role in the overall functionality of the excavator. From basic principles of hydraulic technology to detailed insights on maintenance and troubleshooting, this guide aims to equip operators and enthusiasts alike with the knowledge needed to optimize the performance of their excavators.

Whether you're a seasoned professional or a newcomer to the industry, understanding excavator hydraulic cylinders will enhance your efficiency and effectiveness on the job site.

Understanding the Basics of Hydraulic Cylinders in Excavators

Hydraulic cylinders are the backbone of excavator functionality, providing the necessary force to execute various operations. These hydraulic systems convert hydraulic energy into mechanical energy, allowing excavators to perform tasks such as digging, lifting, and pushing materials efficiently. According to a report by the International Society of Automation, hydraulic cylinders account for nearly 20% of the overall operational costs of heavy machinery, underscoring their significance in construction and mining equipment. By utilizing hydraulic fluid under pressure, these cylinders enable equipment to tackle substantial loads, with some models capable of delivering forces exceeding 60,000 pounds.

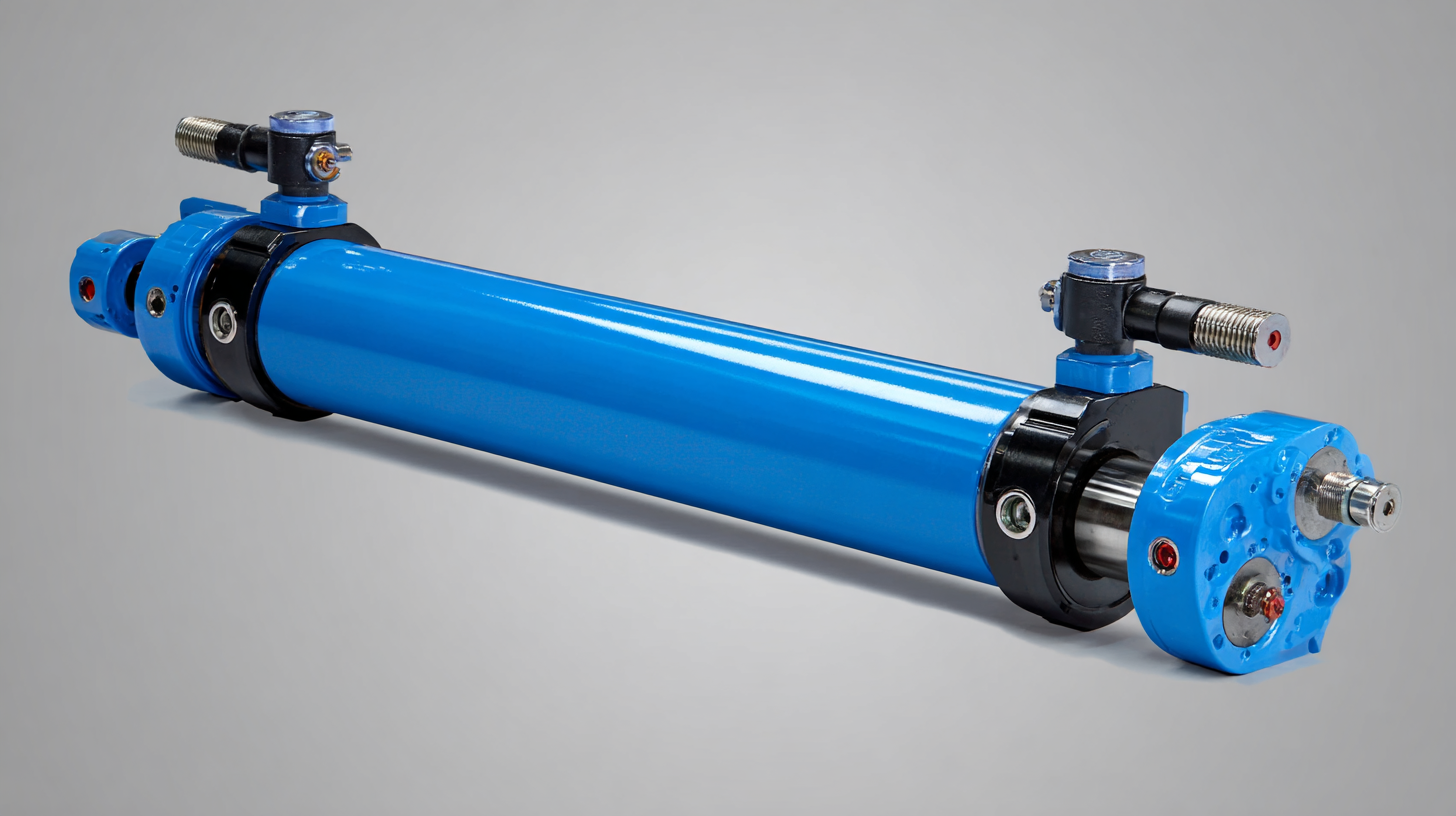

The basic structure of a hydraulic cylinder includes a cylinder barrel, piston, and rod. When hydraulic fluid enters the cylinder, it pushes the piston, which then drives the rod to perform the desired movement. Research by the National Fluid Power Association indicates that proper maintenance of hydraulic systems can improve performance efficiency by up to 30%. Factors such as fluid quality, cylinder seals, and system cleanliness play a crucial role in the longevity and effectiveness of hydraulic cylinders in excavators. Understanding these fundamentals is essential for operators and maintenance personnel, as it directly impacts productivity and operational costs in the heavy equipment sector.

Understanding the Functionality of Excavator Hydraulic Cylinders

| Cylinder Type | Application | Operating Pressure (PSI) | Rod Diameter (inches) | Stroke Length (inches) |

|---|---|---|---|---|

| Boom Cylinder | Boom Lifting | 3000 | 6 | 24 |

| Arm Cylinder | Arm Movement | 3000 | 5 | 27 |

| Bucket Cylinder | Bucket Control | 3500 | 4 | 35 |

| Swing Cylinder | Rotation | 2500 | 7 | 18 |

| Travel Cylinder | Forward/Backward Movement | 3000 | 5.5 | 42 |

Key Components of Excavator Hydraulic Cylinders and Their Functions

Excavator hydraulic cylinders play a crucial role in the functionality of heavy machinery, powering various movements such as lifting, rotating, and digging. Key components of these hydraulic cylinders include the cylinder tube, piston, seals, and hydraulic fluid. The cylinder tube serves as the housing for the piston, which creates the force necessary for movement. Seals within the cylinder are essential for preventing leaks, ensuring that the hydraulic fluid remains contained and under pressure, thus enabling optimal operation.

Tips: Regular maintenance of hydraulic cylinders is vital for prolonging their lifespan. Always check for fluid leaks around seals, as this can indicate wear and tear. Additionally, ensuring that the hydraulic fluid levels are adequate will help maintain performance.

Another important element is the hydraulic fluid itself, which transmits force throughout the system. The quality and type of hydraulic fluid can greatly affect the efficiency and responsiveness of the hydraulic cylinders. Choosing the right fluid and maintaining its cleanliness can prevent damaging contaminants from affecting the system.

Tips: Use high-quality hydraulic fluid recommended for your specific excavator model. Regularly change the fluid and filters based on the manufacturer’s guidelines to ensure optimal performance and avoid costly repairs.

How to Diagnose Common Issues with Excavator Hydraulic Cylinders

When it comes to the efficient operation of excavators, the hydraulic cylinders play a pivotal role. However, these critical components can experience common issues that may hinder performance. To diagnose problems with hydraulic cylinders, it is essential to recognize the early signs of malfunction. A noticeable decrease in lifting power or slow response times when operating the excavator can indicate potential hydraulic issues. Additionally, any visible leaks around the hydraulic cylinder seals should raise immediate concern, as this can lead to fluid loss and decreased efficiency.

Another vital diagnostic step is to check the hydraulic fluid levels and quality. Contaminated or low hydraulic fluid can cause operational problems, including erratic movements and unexpected stops. Regularly inspecting the hydraulic system for air bubbles or froth in the fluid can also signal underlying issues, as these can affect the cylinder's performance. By recognizing these symptoms early on, operators can address minor problems before they escalate, ensuring that their excavators remain in peak operating condition.

Steps for Proper Maintenance of Hydraulic Cylinders in Excavators

Hydraulic cylinders are vital components of excavators, enabling them to perform a wide range of functions, from lifting and digging to rotation and unloading. To ensure optimal performance and longevity of these cylinders, proper maintenance is crucial. Regular inspections should be conducted to check for leaks, wear, and any other signs of damage. Additionally, topping up hydraulic fluid and cleaning or replacing filters can prevent issues that may arise from contamination and inadequate lubrication.

As the summer months approach, extreme temperatures can impact the effectiveness of hydraulic systems. Therefore, operators should implement a preventive maintenance plan that includes monitoring hydraulic fluid temperature and tracking the usage of the equipment. Utilizing technology to maintain records ensures that no major maintenance intervals are overlooked, thus protecting both the machinery and the individuals operating it.

A well-maintained hydraulic system not only enhances performance but also contributes to the safety and efficiency of operations on construction sites.

Upgrading and Replacing Hydraulic Cylinders: A Step-by-Step Guide

When it comes to maintaining the efficiency and performance of excavators, understanding the process of upgrading and replacing hydraulic cylinders is crucial. According to industry reports, hydraulic cylinders account for approximately 30% of machinery downtime in heavy equipment. Therefore, timely upgrades can significantly enhance operational productivity. This step-by-step guide will assist operators and mechanics in effectively managing this vital aspect of excavator maintenance.

Tip 1: Before beginning any upgrade, assess the existing hydraulic cylinder's performance. Look for signs of wear, such as leaks or unusual noises, which can indicate the need for replacement. Performing a thorough inspection can prevent unexpected failures and promote longer equipment life.

To start the upgrade process, first ensure that you have the correct replacement cylinder that meets the original specifications provided by the manufacturer. Next, follow a systematic disassembly of the old cylinder. Statistics show that improper removal can lead to damaging other components, resulting in additional repair costs. Once the new cylinder is fitted, always double-check hydraulic connections to prevent leaks.

Tip 2: Regularly scheduled maintenance checks should include inspections of hydraulic cylinders to catch issues early. Preventive measures not only prolong the lifespan of your equipment but also optimize performance and safety during operation.

Related Posts

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

Ultimate Guide to Understanding Hydraulic Cylinders for Excavators in Global Markets

-

Understanding the Best Hydraulic Oil Cylinder Types for Your Needs

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors

-

Ultimate Guide to Choosing the Right Hydraulic Cylinder for Excavators with Key Specs and Tips