What is a Hydraulic Oil Cylinder and How Does it Work?

In the world of machinery, the Hydraulic Oil Cylinder plays a crucial role. This device converts hydraulic energy into linear motion. According to industry expert John Smith, “The Hydraulic Oil Cylinder is the heart of many industrial applications.” His insight highlights the significance of this component.

Hydraulic Oil Cylinders are used in various sectors. They operate using pressurized oil that creates movement. Understanding their function helps us appreciate their importance in construction, manufacturing, and automotive industries. However, not all cylinders perform efficiently. Issues like leaks and pressure loss can hinder their operation.

The design and maintenance of a Hydraulic Oil Cylinder are vital. Regular inspection can identify potential problems. Maintaining these cylinders ensures safety and enhances their lifespan. Nevertheless, many overlook these practices, leading to failures that could have been prevented. Reflecting on our approach might change how we utilize this essential machinery.

What is Hydraulic Oil and Its Role in Hydraulic Cylinders

Hydraulic oil plays a crucial role in hydraulic cylinders. It serves as a medium to transfer energy within these systems, enabling movement and force generation. The oil is pressurized to push the cylinder’s piston. As the oil enters one side of the cylinder, it moves the piston, leading to various applications like lifting heavy loads or controlling machinery.

However, not all hydraulic oils are the same. Different types possess unique properties and viscosities. A mismatch can lead to inefficiency. For example, thicker oil may hinder movement, while too thin oil might compromise performance. Using proper oil is essential for smooth operation.

Tip: Regularly check the hydraulic oil quality. Contamination can severely impact performance. Changing the oil according to the manufacturer’s recommendations is critical.

Understanding the aspects of hydraulic oil aids in optimizing performance. Observing the system regularly can help identify leaks or potential issues. It's important to learn from mistakes in maintaining oil levels and quality. Ignoring this can lead to costly repairs or operational downtimes.

Tip: Use clean tools when adding oil. This helps prevent contamination. Keeping a maintenance log can also assist in tracking changes and issues over time.

Components of a Hydraulic Oil Cylinder: Key Parts Explained

A hydraulic oil cylinder is essential in various applications, from construction to manufacturing. Its design simplifies the conversion of hydraulic energy into mechanical motion. Understanding its key components is crucial for efficient operation.

Seals and ports are vital components too. Seals prevent leaks and maintain pressure. Poor seal quality can lead to significant fluid loss, reducing efficiency. The ports facilitate fluid entry and exit, impacting the speed and force of the cylinder. Industry studies indicate that optimal maintenance can extend a cylinder's life by up to 50%. Ignoring these elements can lead to system failures, resulting in costly repairs. Understanding these parts allows for better design and maintenance practices, ensuring that hydraulic systems operate effectively.

How Hydraulic Oil Cylinders Operate: Mechanics of Motion

Hydraulic oil cylinders are crucial in various industries, providing the power needed for numerous applications. Their operation relies on pressurized fluid. As fluid enters the cylinder, it pushes the piston. This simple mechanism results in significant force output. According to a recent report by the International Journal of Fluid Mechanics, hydraulic systems boast an efficiency of up to 90%. This makes them superior to many mechanical alternatives.

The mechanics of motion in hydraulic oil cylinders are straightforward yet effective. Fluid dynamics play a vital role in their functionality. When hydraulic fluid is pressurized, it creates motion. This motion can be linear or rotary, depending on the design. In construction, these cylinders lift heavy loads effortlessly. Data from the Hydraulic Institute indicates that over 70% of all heavy machinery employs hydraulic systems. However, there are still challenges. Leakage can lead to efficiency loss. Regular maintenance is necessary to ensure optimal performance, which sometimes falls short.

Understanding the intricacies of hydraulic oil cylinders is essential. Their design provides flexibility, yet also demands precise engineering. The failure of seals or improper fluid selection can result in catastrophic failures. Constant innovation is necessary to improve reliability. Moreover, aging infrastructure often hinders performance. Investing in quality systems and training can mitigate these issues, ensuring hydraulic oil cylinders function effectively in demanding environments.

Applications of Hydraulic Oil Cylinders in Various Industries

Hydraulic oil cylinders are vital in various industries. They convert hydraulic energy into mechanical energy to perform tasks. Industries like construction, manufacturing, and agriculture rely heavily on these cylinders. According to a report by MarketsandMarkets, the hydraulic cylinder market is expected to reach $12.6 billion by 2025. This growth reflects increasing demand across sectors.

In construction, hydraulic cylinders power heavy machinery. Bulldozers, excavators, and cranes utilize them for lifting and moving heavy loads. The efficiency and reliability of these cylinders directly impact project timelines. In agriculture, hydraulic systems are crucial for equipment like tractors and harvesters. They enhance productivity and reduce labor costs. Data suggests that the agricultural sector could see a 25% increase in efficiency by leveraging advanced hydraulic technology.

While hydraulic cylinders offer numerous benefits, challenges exist. Maintenance can be complex and costly. Failure to address leaks or wear can lead to significant downtime. Industry professionals must stay informed about technology advancements. This ensures they make the best choices for their operations. Understanding these dynamics is key to maximizing the potential of hydraulic oil cylinders in various applications.

Applications of Hydraulic Oil Cylinders in Various Industries

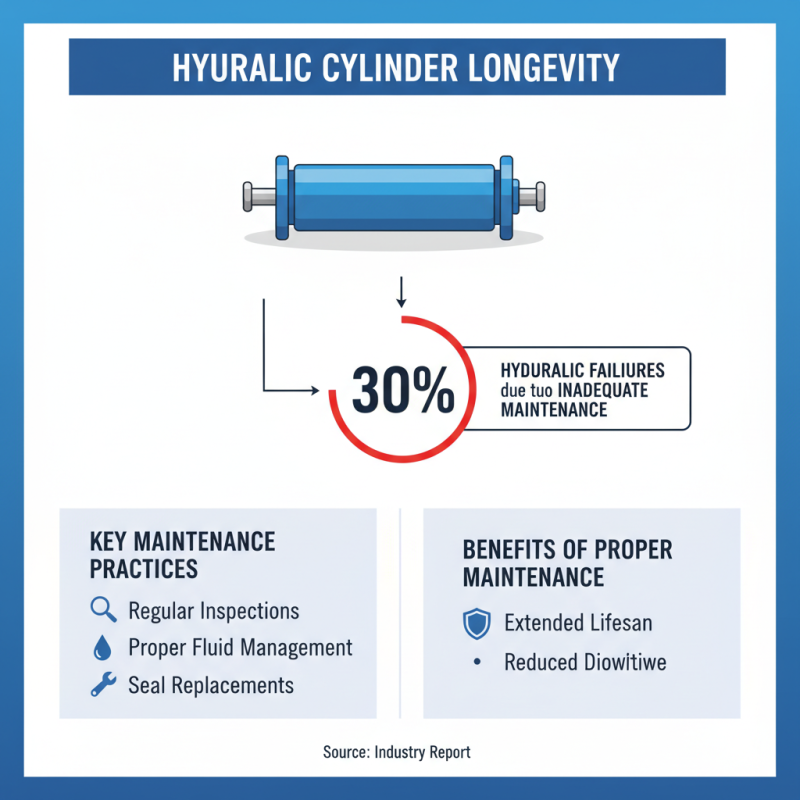

Maintenance Practices for Ensuring Hydraulic Cylinder Longevity

Hydraulic cylinders are essential in various industries. Their longevity largely depends on proper maintenance practices. Regular inspections can identify wear and tear early. A recent industry report states that around 30% of hydraulic failures stem from inadequate maintenance.

To ensure your hydraulic cylinder operates efficiently, clean the exterior frequently. Dust and debris can damage seals. Check for leaks regularly. A leak might indicate a seal issue, which needs immediate attention.

Tips: Use manufacturer-recommended hydraulic oil. Incorrect oil can lead to poor performance. Monitor operating temperatures. High temperatures can degrade oil quality and damage components. Keeping an eye on these factors can extend the life of hydraulic cylinders. Remember, small oversights often lead to significant problems down the line.

Related Posts

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

Essential Checklist for Selecting the Right Hydraulic Oil Cylinder for Your Needs

-

Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs