Maximize Efficiency: The Ultimate Guide to Choosing Hydraulic Cylinders for Your Forklift

When selecting the right hydraulic cylinder for forklift applications, understanding the various types available is essential to maximize efficiency and performance. Hydraulic cylinders are vital components that facilitate the lifting and lowering of loads, making them indispensable in material handling operations. Each type of hydraulic cylinder for forklift serves a specific purpose, ranging from lifting heavy loads to supporting stabilization and maneuverability.

In this guide, we will explore the different types of hydraulic cylinders, their features, and their applications, enabling you to make informed choices that enhance productivity and safety in your operations. By knowing which hydraulic cylinder for forklift fits your requirements best, you can ensure optimal performance and durability, ultimately leading to improved operational efficiency.

Understanding Forklift Hydraulic Cylinders: Key Features and Types

When selecting hydraulic cylinders for your forklift, understanding the key features and various types available is crucial for maximizing efficiency. Hydraulic cylinders are essential components that provide lifting and lowering capabilities. The main features to consider include bore diameter, stroke length, and pressure ratings. A larger bore diameter can lift heavier loads, while a longer stroke length allows for greater lifting heights. Additionally, the pressure rating indicates the maximum force the cylinder can handle without failure, ensuring safety during operation.

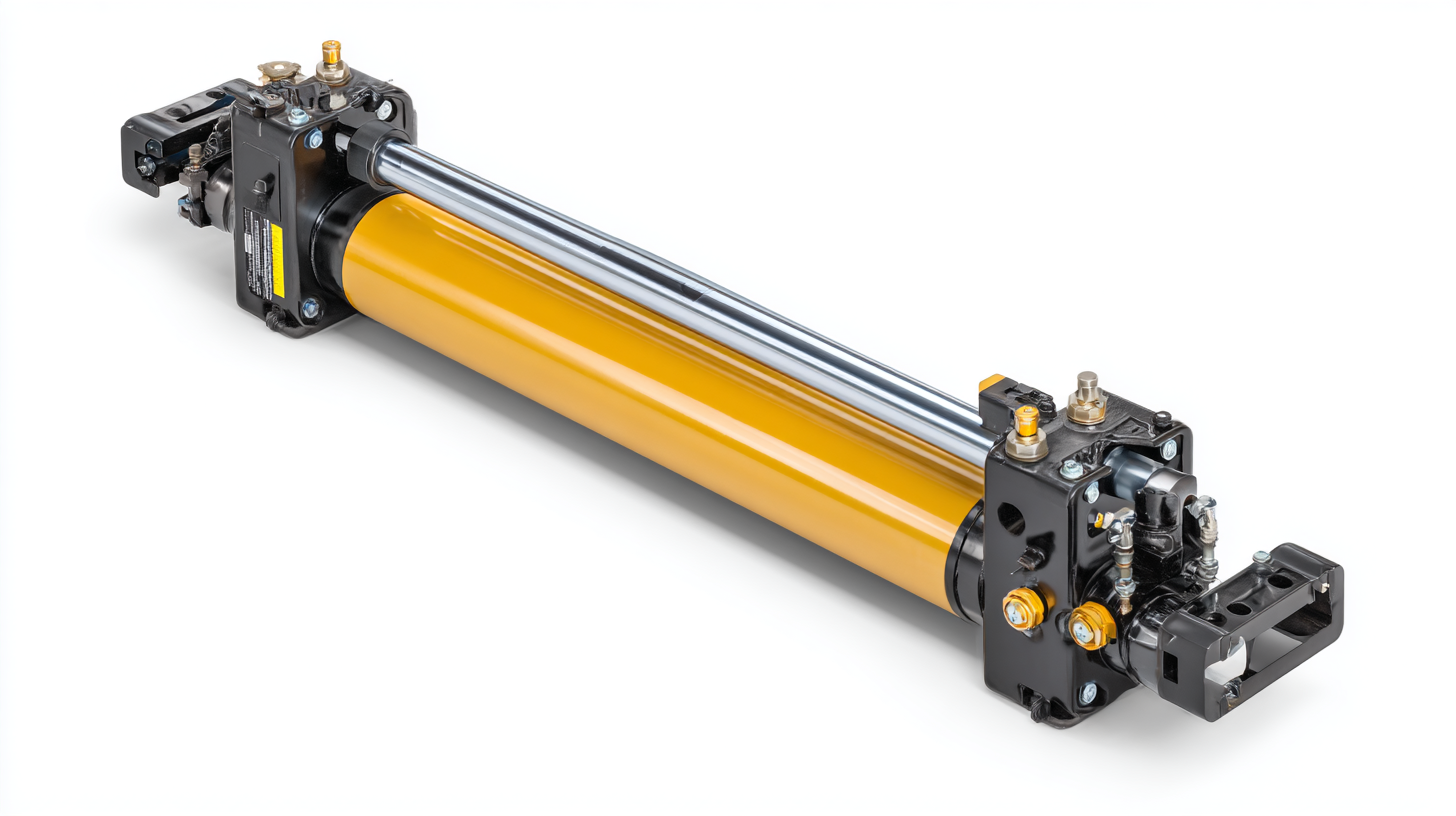

There are several types of hydraulic cylinders commonly used in forklifts. Tie rod cylinders, known for their durability and ease of maintenance, consist of a cylinder barrel connected by tie rods at both ends. In contrast, welded cylinders offer a compact design and robust construction, often preferred in applications with limited space. Other options include telescopic cylinders, which provide a significant reach while maintaining a smaller retracted size. Understanding these features and types will help you make informed decisions, improving the performance and longevity of your forklift’s hydraulic system.

5 Essential Factors for Choosing the Right Hydraulic Cylinder

When it comes to selecting hydraulic cylinders for forklifts, understanding the key factors can significantly enhance operational efficiency. According to a report by the National Forklift Safety Protocol, over 30% of forklift performance issues stem from improper hydraulic specifications. Therefore, considering the right diameter and stroke length is essential. A well-matched hydraulic cylinder can guarantee optimal lifting capacities and contribute to reducing downtime, ultimately leading to an increase in productivity.

Another critical factor is the working pressure of the hydraulic cylinder. Industry standards indicate that using cylinders rated for higher pressures than the typical operating range of 2,500 to 3,000 psi can improve performance and reliability. This margin not only ensures safety but also accommodates potential future demands. Additionally, the cylinder's material and sealing technology should be evaluated to ensure durability in various environmental conditions. A study by the American Society of Mechanical Engineers highlights that using advanced seal materials can enhance the lifecycle of hydraulic systems by up to 50%, reducing maintenance costs and downtime for operators.

Top 3 Brands for Reliable Forklift Hydraulic Cylinders

When selecting hydraulic cylinders for forklifts, reliability is paramount. Among the top brands known for their superior hydraulic cylinders are Parker Hannifin, Bosch Rexroth, and Enerpac. According to a 2022 market report by Allied Market Research, the industrial hydraulic systems market is projected to reach $21.46 billion by 2025, underscoring the importance of choosing high-quality components like hydraulic cylinders.

Parker Hannifin is recognized worldwide for its extensive range of hydraulic products. Their cylinders are engineered for durability and performance, often featuring advanced sealing technologies that extend service life and reduce maintenance costs. Bosch Rexroth, another industry leader, offers modular hydraulic systems that provide flexibility and efficiency, aligned with the growing demand for custom solutions in material handling equipment. Finally, Enerpac is highly regarded for its heavy-duty hydraulic cylinders, designed to withstand tough operating conditions, making them ideal for high-performance forklift applications.

Investing in reliable hydraulic cylinders from these trusted brands can significantly enhance the efficiency and longevity of your forklift operations, ultimately leading to a more productive work environment.

Maximize Efficiency: Hydraulic Cylinders Performance in Forklifts

7 Common Mistakes to Avoid When Selecting Hydraulic Cylinders

When selecting hydraulic cylinders for forklifts, it’s crucial to avoid common pitfalls that can lead to inefficiencies and increased costs. One major mistake is underestimating the load requirements. According to a report by the Industrial Hydraulics Association, 40% of hydraulic system failures stem from mismatched cylinder specifications. Ensuring that the hydraulic cylinder is rated for the maximum weight your forklift will need to lift is essential for both safety and performance.

Another frequent error is neglecting the operating environment. Many operators fail to consider factors such as temperature extremes and exposure to contaminants, which can severely affect cylinder performance and longevity. A study from the National Fluid Power Association indicates that cylinders operating in harsh conditions can exhibit a reduction in efficiency by up to 30%. It is vital to choose cylinders with appropriate seals and materials designed for your specific working conditions to prevent premature wear and breakdowns.

Another frequent error is neglecting the operating environment. Many operators fail to consider factors such as temperature extremes and exposure to contaminants, which can severely affect cylinder performance and longevity. A study from the National Fluid Power Association indicates that cylinders operating in harsh conditions can exhibit a reduction in efficiency by up to 30%. It is vital to choose cylinders with appropriate seals and materials designed for your specific working conditions to prevent premature wear and breakdowns.

Maximizing Performance: Best Practices in Hydraulic Cylinder Maintenance

Maintaining hydraulic cylinders is crucial for ensuring the optimal performance of forklifts, which are integral to material handling in various industries. According to the International Fluid Power Society, regular maintenance can extend the lifespan of hydraulic components by up to 50%. A proactive maintenance schedule should include regular inspections for leaks, ensuring that seals are intact, and verifying that hydraulic fluid levels are appropriate. Neglecting these aspects can lead to reduced efficiency and increased downtime—a significant concern, as studies show that forklift downtime accounts for approximately 15% of operational costs.

Furthermore, cleanliness is paramount in hydraulic systems; according to a report by the Fluid Power Journal, more than 80% of hydraulic failures are attributed to contamination. Implementing best practices such as using high-quality filters and maintaining a clean work environment can prevent impurities from entering the system. Operators should also perform routine fluid analysis to monitor contamination levels, enabling prompt corrective actions. By prioritizing hydraulic cylinder maintenance, businesses can not only enhance forklift performance but also achieve substantial cost savings and reduce operational disruptions.

Related Posts

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

7 Essential Tips to Maximize Efficiency with Hydraulic Oil Cylinders: Improve Performance by 30%!