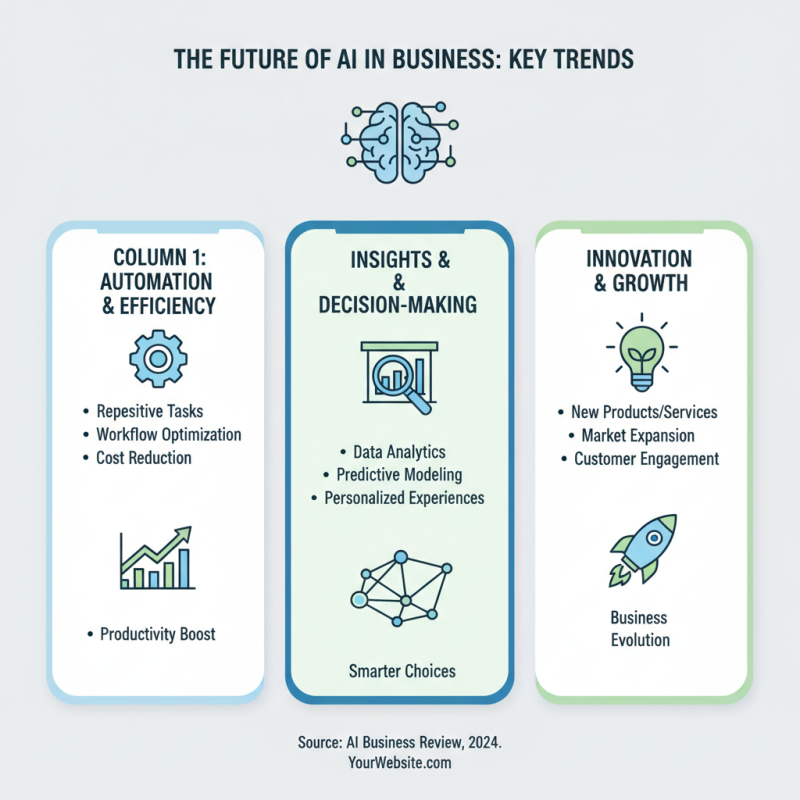

What is a Telescopic Cylinder and How Does it Work?

A Telescopic Cylinder is a fascinating mechanical device known for its compact design and powerful functionality. It consists of multiple nested cylinders that extend and retract. This design allows for significant stroke lengths while maintaining a small collapsed size. In industries like construction and manufacturing, telescopic cylinders play a crucial role. They lift heavy loads in tight spaces.

Understanding how a Telescopic Cylinder works requires looking at its hydraulic principles. Fluid pressure moves the inner cylinders, creating movement. Each stage of the cylinder adds a bit more reach, making it highly efficient. The operation is straightforward yet effective. However, maintenance can be tricky. Regular checks are vital to prevent leaks or hydraulic failures.

The applications of these cylinders are diverse yet not without challenges. They are commonly used in dump trucks and aerial lifts. While they offer immense power, users must be cautious. Misuse can lead to accidents or equipment damage. Knowledge of the Telescopic Cylinder’s capabilities and limitations is critical for safe operation.

Definition and Basic Components of a Telescopic Cylinder

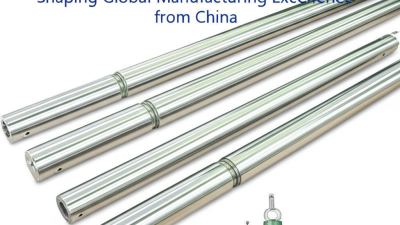

A telescopic cylinder is crucial in various fields like construction and manufacturing. It is designed to extend and retract, providing flexibility and efficiency. These cylinders consist of multiple layers, often called stages or tubes. Each stage slides within the other, allowing for significant length variation in a compact design.

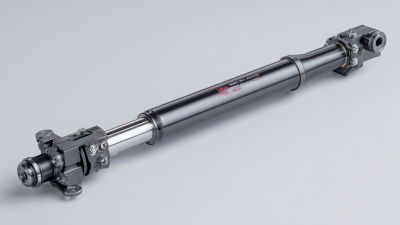

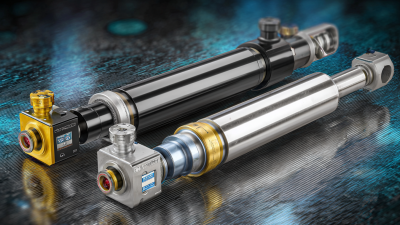

The basic components of a telescopic cylinder include the outer cylinder, inner tubes, and seals. The outer cylinder, or barrel, forms the main body. Inner tubes are fitted inside, with each able to slide independently. Seals prevent hydraulic fluid leaks, maintaining pressure and performance.

Tips: When choosing a telescopic cylinder, consider the working environment. High dust or moisture can impact seals. Regular maintenance is essential. Check for wear and tear regularly. This proactive approach can save costly repairs later.

Understanding the key components helps in troubleshooting. If the cylinder doesn’t function smoothly, examine the seals first. They often wear out before other parts. A thorough inspection can reveal underlying issues. This knowledge aids in making informed decisions for repairs or replacements.

Principle of Operation: How Telescopic Cylinders Function

Telescopic cylinders are fascinating devices designed to extend and contract. They consist of multiple nested tubes that slide within each other. This design allows for a significant extension in a compact package. When activated, hydraulic fluid or air moves through these tubes, pushing them apart.

The operation principle relies on pressure differences. For instance, when pressure builds up, it forces the outer tubes to extend. This action can lift heavy loads easily. However, it can also lead to stability issues if not properly balanced. Careful monitoring of the pressure is necessary. Too much pressure can damage the cylinder.

Maintenance is crucial for efficiency. Regular inspections help identify wear and avoid failures. Understanding how these components work promotes better usage. Users sometimes overlook basic safety guidelines, leading to accidents. A simple mistake can lead to expensive repairs or injuries. Learning the proper operation of telescopic cylinders is essential.

Applications of Telescopic Cylinders in Various Industries

Telescopic cylinders are widely used across various industries due to their unique ability to extend and retract. In construction, these cylinders support heavy machinery like cranes and excavators. According to a market report by Research and Markets, the global hydraulic cylinder market is projected to reach $18 billion by 2025. The demand for durable telescopic cylinders is a significant factor contributing to this growth.

In the automotive sector, telescopic cylinders play a crucial role in lifting and lowering vehicle components. For example, they are used in hydraulic lifts to enhance vehicle maintenance efficiency. Furthermore, in the shipping industry, these cylinders facilitate the loading and unloading of cargo containers. With the rise of e-commerce, the need for efficient logistics solutions has increased. The use of telescopic cylinders can optimize workflow, yet many companies still struggle with maintenance issues that can lead to costly downtime.

Agriculture also benefits from telescopic cylinders, especially in modern equipment like tractors. They aid in the precise control of attachments, which boosts productivity. However, industries often overlook the importance of regular inspections and replacements. A small oversight can lead to failures, impacting overall operations. Reports suggest that many firms miss out on maximizing the potential of telescopic technology due to insufficient training and awareness. Recognizing these gaps can lead to better implementation and significant efficiency gains.

Advantages and Limitations of Using Telescopic Cylinders

Telescopic cylinders are popular in various applications, providing efficient movement. Their primary advantage is their compact design. They extend and retract, allowing for great versatility in tight spaces. This makes them ideal for construction equipment and automotive industries.

However, telescopic cylinders also have limitations. They can be more complex than standard cylinders. This complexity sometimes leads to maintenance challenges. Improper care may result in leaks or malfunction. Additionally, the extended length can impose stability issues during operation. Users must consider these factors when deciding on their application.

While telescopic cylinders offer unique benefits, potential drawbacks should not be overlooked. Regular inspection and maintenance are crucial. A small oversight in upkeep can lead to significant problems. Understanding both pros and cons helps in making informed choices. This balance is essential for optimal performance in any project.

Maintenance and Troubleshooting for Telescopic Cylinders

Telescopic cylinders are powerful hydraulic components used in various machinery. Keeping them functioning well requires regular maintenance. Neglect can lead to significant issues. A simple visual inspection can help detect leaks or damage. Look for any signs of wear, such as deep scratches or rust.

Lubrication is crucial for smooth operation. Applying the right lubricant avoids friction and prevents wear. However, over-lubricating can attract dirt and cause buildup. Remember, keeping seals in good condition is equally important. Damaged seals can lead to hydraulic fluid leaks, affecting performance and safety. Replace seals promptly to prevent further damage.

Troubleshooting is key when problems arise. Listen for unusual sounds during operation; this can indicate issues with the cylinder. If it's moving unevenly, check for blockages. A small grain of sand can disrupt function. Open the cylinder to assess and clean the internals when necessary. Regular maintenance checks are essential, but remain vigilant for unexpected failures.

Telescopic Cylinder Maintenance and Troubleshooting

Related Posts

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

How to Choose the Right Telescopic Cylinders Underbody for Optimal Performance

-

Exploring Alternative Solutions for Telescopic Cylinders Underbody Applications

-

Maximizing Efficiency and Performance with Telescopic Cylinder Innovations in the Hydraulic Industry

-

How to Choose Telescopic Cylinders for Underbody Applications?