Top Hydraulic Cylinder For Excavator Picks for 2026?

When it comes to excavators, the hydraulic cylinder plays a crucial role. It's vital for lifting, digging, and other functions. Choosing the right hydraulic cylinder for excavator can significantly impact performance and efficiency.

In 2026, customers will see a variety of options. Each model comes with unique features, tailored for specific tasks. This makes it essential to explore these options carefully. Whether for construction, mining, or demolition, the right hydraulic cylinder is key. You can't underestimate its importance.

However, selecting a hydraulic cylinder for excavator is not always straightforward. Brands vary in quality and price. Some might offer lower prices but lack durability. Buyers should reflect on their choices and needs before making a decision. Understanding the specific requirements of operations is crucial for success. This exploration will help in identifying the best hydraulic cylinders available in 2026.

Top Features to Consider When Choosing Hydraulic Cylinders for Excavators

When selecting hydraulic cylinders for excavators, several key features are essential. The bore size greatly influences performance. A larger bore translates to increased lifting capacity. Nonetheless, bigger isn't always better. It can add weight and decrease fuel efficiency. Many users overlook this balance, leading to inefficiencies.

Stroke length is another critical aspect. Longer strokes allow for greater working versatility. However, they can complicate the design. Some excavators may not accommodate longer cylinders due to space constraints. It’s important to assess the specific application and machine size. This decision requires careful thought and might require adjustments later.

Seal design and material are also vital. Quality seals minimize leaks and enhance durability. Different jobs may demand various materials, so understanding the working conditions is crucial. Some users neglect this aspect, leading to premature wear or failures. Ultimately, weighing these factors thoughtfully can lead to a more efficient and reliable hydraulic cylinder choice.

Leading Brands of Hydraulic Cylinders for Excavators in 2026

When it comes to hydraulic cylinders for excavators, 2026 is expected to see a surge in demand. According to a report by MarketsandMarkets, the hydraulic cylinder market is projected to reach $5.5 billion by 2026, growing at a CAGR of 5.2%. This growth is driven by construction and mining activities worldwide. These industries often rely on highly durable and efficient hydraulic systems. The selection of hydraulic cylinders can greatly influence overall productivity.

Many leading companies are investing in research and development of advanced hydraulic technologies. Innovations like load-sensing systems and smart hydraulic controls are emerging. However, not all manufacturers keep pace with these advancements. Some fall short in providing reliable products. This inconsistency can lead to unexpected downtime and increased operational costs for contractors.

The focus in 2026 should be on quality and performance. Many companies offer extensive warranties and after-sales support, which can vary significantly. It is important to weigh these factors. The right hydraulic cylinder can mean the difference between seamless operation and costly breakdowns. An informed choice will be essential for success in the competitive landscape of excavation.

Innovative Technologies in Hydraulic Cylinder Design for Excavators

The design of hydraulic cylinders for excavators has seen significant advancements recently. Innovative technologies aim to increase efficiency and performance. According to industry reports, hydraulic cylinders now feature improved seal designs that reduce leakage by up to 30%. This innovation not only enhances operational efficiency but also minimizes maintenance costs.

More importantly, the use of advanced materials is changing the landscape. Companies are employing high-strength alloys that improve durability without adding extra weight. This results in a more efficient power-to-weight ratio. Recent studies indicate that these materials can withstand higher pressure ratings, boosting overall productivity.

However, there are challenges in adopting these new technologies. Manufacturers often find that integrating advanced designs into existing machinery requires substantial investment. Additionally, the learning curve for maintenance personnel can hinder immediate implementation. Feedback from operators highlights concerns about adapting to these changes swiftly. Clarifying these issues is crucial as the industry moves forward.

Top Hydraulic Cylinder Performance for Excavators in 2026

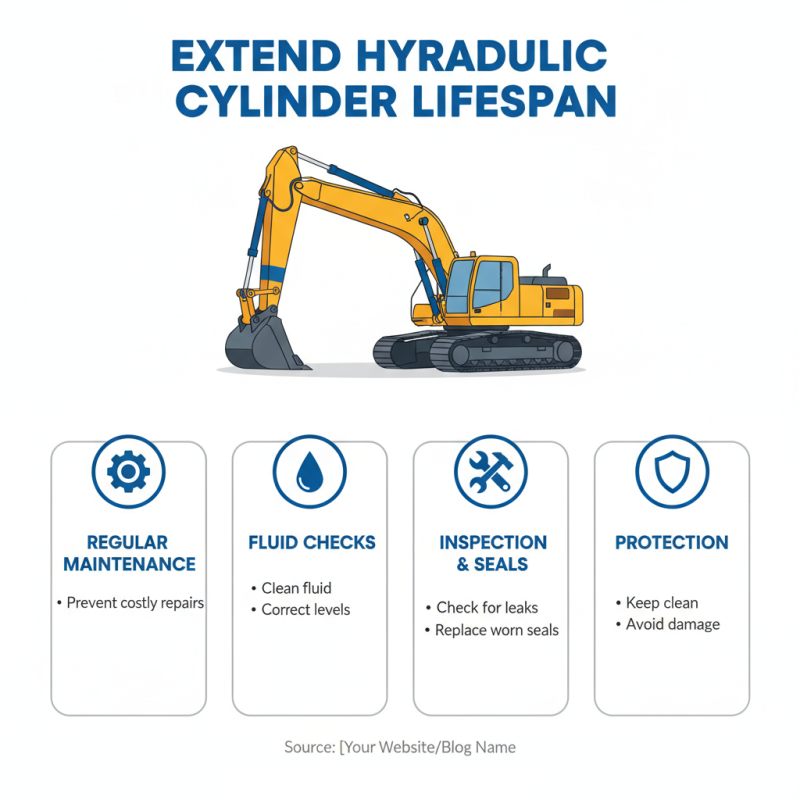

Maintenance Tips for Extending the Life of Excavator Hydraulic Cylinders

Hydraulic cylinders are essential for excavators. Keeping them in good shape is crucial for machinery longevity. Regular maintenance can prevent costly repairs. Here are some tips to extend their life.

Inspect the hydraulic cylinders frequently. Look for signs of wear or leaks. Pay attention to the seals. Small leaks can become big problems. If you notice oil on the surface, act before it worsens. Clean the cylinders regularly. Dirt and grime can cause damage. Use a soft cloth to wipe them down. This simple step can enhance performance.

Always check fluid levels. Low fluid can lead to overheating. This might damage the cylinders and surrounding components. Replace old hydraulic fluid regularly. It’s a small task that can make a big difference. When operating, avoid sudden jerks. Smooth movements reduce stress on the cylinders. Operators often forget this, leading to premature wear. By following these steps, you can keep your hydraulic cylinders working effectively.

Comparative Analysis of Hydraulic Cylinder Performance in Excavator Models

Excavators rely heavily on hydraulic cylinders for performance. Performance metrics show the importance of precise engineering in these components. Recent studies indicate that hydraulic cylinder efficiency in excavators can vary by up to 30%. This disparity affects digging force and cycle times significantly. When looking at several models, some exhibit hydraulic efficiency below the industry standard of 85%.

Material selection also influences performance. High-strength steel is often favored, but its cost can be prohibitive. Lightweight alternatives can reduce fatigue but may compromise durability. Reports reveal that 40% of operators have experienced premature wear in cylinders. These failures typically arise due to poor maintenance or subpar components, suggesting a need for reflection on operational practices.

Field tests suggest that installation is as crucial as design. Incorrect installation can lead to hydraulic leaks and reduced functionality. Some excavator models have shown a 25% increase in downtime due to these issues alone. Regular maintenance is essential but often overlooked. Acknowledging these factors can lead to better performance and longer lifespans for hydraulic cylinders in excavators.

Related Posts

-

Why is the Excavator Hydraulic Cylinder Essential for Performance?

-

Ultimate Guide to Choosing the Right Hydraulic Cylinder for Excavators with Key Specs and Tips

-

Ultimate Guide to Understanding Hydraulic Cylinders for Excavators in Global Markets

-

How to Choose the Right Excavator Hydraulic Cylinder for Your Needs

-

The Ultimate Guide to Choosing the Right Hydraulic Cylinder for Your Excavator Needs

-

Top 10 Benefits of Using an Excavator Hydraulic Cylinder in Construction?