The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

In the rapidly evolving world of industrial machinery and construction equipment, the demand for high-performance components is paramount. Telescopic cylinders underbody play a critical role in enhancing the efficiency and functionality of heavy-duty vehicles and equipment. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach USD 17.3 billion by 2026, growing at a CAGR of 6.2%. This growth underscores the increasing reliance on advanced hydraulic systems, where telescopic cylinders underbody are essential for achieving optimal lifting and lowering capabilities. As global buyers seek reliable sourcing options for these vital components, understanding the intricacies of the market becomes essential. This ultimate guide aims to equip buyers with the necessary insights to navigate the complexities of sourcing telescopic cylinders underbody, ensuring they make informed decisions that align with their operational needs.

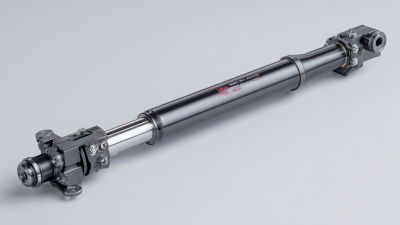

Understanding Telescopic Cylinders: Key Features and Applications

Telescopic cylinders are pivotal in various industrial applications, especially due to their ability to provide considerable force in a compact space. A double acting main cylinder is one of the most common types utilized, allowing movement in both directions by using hydraulic fluid to push and pull. This design is particularly beneficial in construction equipment where efficiency and power are crucial, enabling tasks such as lifting heavy loads or operating machinery with precision.

The hydraulic fluid power cylinder market is anticipated to see tremendous growth, forecasted to reach approximately USD 27.5 billion by 2035. This expansion is driven by increased demand across diverse sectors, including construction and mobile automation. The incorporation of advanced technologies, such as encoder-based sensors for measuring cylinder position, enhances performance and accuracy, making these devices even more integral to modern automated systems. As industries evolve, the significance of understanding key features and applications of telescopic cylinders will only continue to rise.

Identifying Reliable Manufacturers for Telescopic Cylinders Worldwide

When sourcing telescopic cylinders, identifying reliable manufacturers is crucial for global buyers. First, it is important to conduct thorough research to narrow down your options. Utilize industry directories, trade shows, and online platforms to find potential manufacturers. Pay attention to their experience, certifications, and customer reviews. This information can offer insight into their reliability and product quality. A manufacturer with a robust background in telescopic cylinder production is likely to adhere to international standards and provide superior products.

Moreover, establishing clear communication with potential manufacturers is key. Engage them early in the sourcing process to discuss your specific requirements, lead times, and pricing. A responsive and transparent manufacturer is indicative of a trustworthy partner. Don't hesitate to ask for references or even sample products to evaluate their quality firsthand. Understanding their production capabilities and adherence to quality control measures can further assure you of their reliability. By diligently vetting manufacturers, global buyers can ensure a successful sourcing experience for telescopic cylinders.

Quality Standards and Certifications for Telescopic Cylinders Procurement

When procuring telescopic cylinders, understanding quality standards and certifications is paramount for global buyers. Adhering to industry benchmarks such as ISO 9001 ensures that suppliers maintain consistent quality management systems. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach $12.02 billion by 2025, which underscores the importance of sourcing cylinders that meet strict quality requirements. More specifically, telescopic cylinders should comply with industry standards like the American National Standards Institute (ANSI) and the European Norm (EN), which govern performance and safety.

Tips: Always request documentation of compliance with ISO and other relevant standards from your suppliers. This not only ensures product quality but also builds trust in your business relationships.

Additionally, certifications such as CE marking and RoHS compliance can indicate a supplier's commitment to safety and environmental standards. According to the International Organization for Standardization (ISO), certified products typically show a 20-30% reduction in defects during manufacturing, which is vital when selecting telescopic cylinders for demanding applications.

Tips: Regularly review your suppliers' certifications, as these can change. Maintain an updated checklist of required certifications to streamline your procurement process.

Cost Considerations: Budgeting for Telescopic Cylinder Sourcing

When it comes to sourcing telescopic cylinders, budget considerations play a critical role in the decision-making process. Understanding the costs associated with these components can help global buyers make informed choices that align with their financial plans. First, evaluate the overall budget by taking into account not just the purchase price of the cylinders, but also potential shipping costs, tariffs, and customs fees, which can significantly impact the final expense.

Tip 1: Always request detailed quotes from multiple suppliers. This will help you compare not only the prices of the cylinders but also the associated costs of delivery and handling. Keep an eye out for hidden fees that could arise during the importation process, as these can add up quickly.

Tip 2: Consider the long-term value over the initial cost. Cheaper cylinders may seem attractive but could lead to higher maintenance costs and reduced efficiency. Investing in quality products can lead to savings in repairs and replacements down the line, making them a more cost-effective choice in the long run.

Establishing a realistic budget that includes all potential expenses will enable you to navigate the sourcing process more effectively, ensuring that you choose the right telescopic cylinders without compromising on quality or features.

Navigating International Shipping and Customs for Telescopic Cylinders

When sourcing telescopic cylinders for underbody applications, understanding international shipping and customs regulations is paramount. Each country has unique requirements that can impact the shipping process significantly. Buyers should be aware of import duties, restrictions, and necessary documentation, which may include technical specifications or compliance certificates.

**Tips:** Always research the destination country’s customs regulations before shipping. This helps avoid unexpected delays and extra costs. Collaborate with a logistics partner experienced in international shipping to ensure compliance and streamline the shipping process.

Moreover, proper labeling and packaging are crucial. Incorrectly labeled shipments can lead to customs holds, incurring additional costs. Ensuring that your telescopic cylinders are packed securely and labeled according to international standards will help facilitate smoother clearance.

**Tips:** Utilize standardized shipping containers and include detailed invoices with your shipments. Accurately declare the contents and their value to avoid any compliance issues during clearance. Regular communication with your shipping provider can help you stay updated on any changes in international shipping regulations.

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers - Navigating International Shipping and Customs for Telescopic Cylinders

| Country | Average Price (USD) | Shipping Time (Days) | Customs Process Duration (Days) | Import Duty (%) |

|---|---|---|---|---|

| United States | 250 | 5 | 2 | 5 |

| Germany | 300 | 7 | 3 | 6 |

| China | 150 | 10 | 5 | 10 |

| Canada | 270 | 6 | 4 | 5 |

| Australia | 320 | 12 | 6 | 7 |

Related Posts

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

Essential Tips for Identifying Reliable Manufacturers of Best Telescopic Cylinders Underbody

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs